Industrial facilities often operate under extreme conditions where exposure to acids, alkalis, moisture, heat, abrasion and other harsh elements is part of daily life. Over time, these factors can significantly impact both protective linings and the concrete structures they safeguard.

Understanding how environmental conditions influence material performance is essential for selecting the right lining system and ensuring long-term durability.

1. The Role of pH: Chemical Attack and Material Compatibility

Concrete is naturally alkaline, with a pH around 12 to 13 when originally placed. This high alkalinity helps protect embedded steel reinforcement from corrosion. However, when exposed to acidic environments (pH below 7), concrete begins to deteriorate as acids react with calcium hydroxide in the cement paste, dissolving the material and weakening the structure.

Protective linings act as a barrier, preventing acid or alkali infiltration. But not all linings perform equally across the pH spectrum:

- Epoxy-based systems are ideal for mildly acidic or neutral environments and most alkalis

- Novolak and vinyl ester systems resist stronger acids and solvents

- Silicate-based materials excel in extremely acidic or high-temperature environments often found in wastewater, chemical processing, refining or flue gas applications

Key takeaway: Always match the chemical resistance of the lining system to the expected pH range, acid or alkali concentration and temperature of service conditions.

2. Temperature: The Hidden Stress Factor

Temperature has a direct impact on both concrete and protective linings.

- Thermal expansion and contraction: Different materials expand and contract at different rates. When the temperature fluctuates, stresses develop between the concrete substrate and the lining, potentially causing cracking or delamination.

- High temperatures: Elevated heat can soften resin-based systems or accelerate chemical degradation, as higher temperatures typically increase the aggressiveness of most chemicals

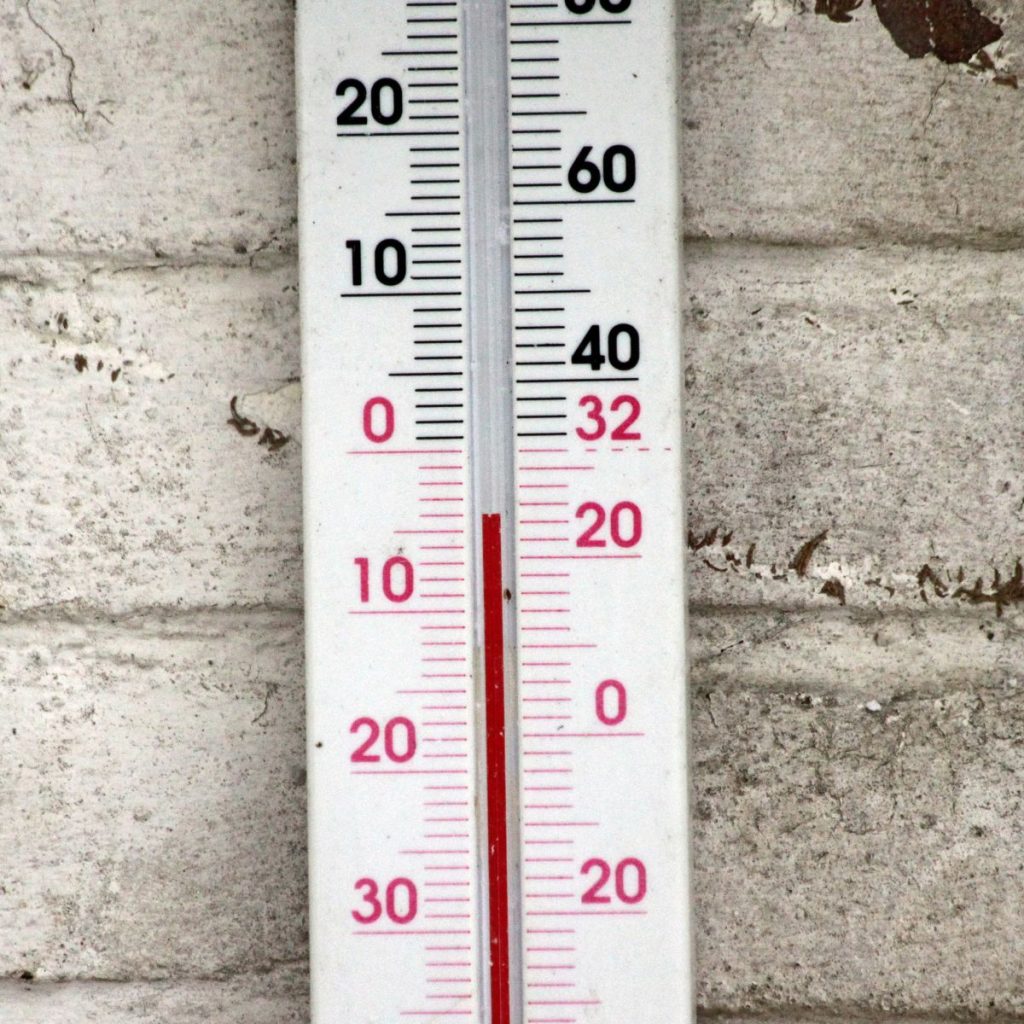

- Low temperatures: Cold conditions, typically below freezing, can make coatings brittle, reducing flexibility and adhesion

To manage these stresses, it’s important to use materials designed for thermal stability and apply them under proper curing conditions. Most coatings and linings cannot be exposed to temperatures below freezing during application and curing.

Key takeaway: Always consider both the operating and ambient temperature ranges during system selection, application and curing.

3. Moisture and Vapor Transmission

Concrete is porous, it absorbs and transmits moisture. When a dense, impermeable lining is applied over damp concrete, trapped vapor can lead to blistering or loss of adhesion/ bond. Adhesion is also negatively affected when too much moisture is present in the pores of the concrete, limiting the lining system’s ability to penetrate into the pores of the concrete and bond properly. Moisture also promotes corrosion of reinforcing steel and accelerates chemical attack from within.

Using moisture–tolerant primers, vapor permeable systems, or ensuring thorough substrate drying before application can mitigate these risks.

Key takeaway: Moisture control is critical to ensure strong adhesion and long–term lining performance.

4. Mechanical Stress and Surface Movement

Even when chemistry and temperature are controlled, mechanical factors such as vibration, impact, abrasion or structural movement can damage linings. Systems that are strong but also offer flexibility and crack-bridging capabilities help absorb stress without compromising protection.

Key takeaway: Evaluate not only chemical exposure but also the physical demands placed on the surface of the lining system.

5. The Importance of Comprehensive Assessment

No single factor (pH, temperature, or moisture) operates in isolation. In most facilities, these conditions interact, compounding their effects. Conducting a full site assessment and consulting with experienced material specialists ensures the chosen lining system will perform as intended.

Key takeaway: Real-world durability depends on knowledge of the substrate conditions, the right chemistry, surface preparation, and installation.

Protecting Concrete for the Long Run

Concrete may seem indestructible, but in aggressive service environments, it requires protection. By understanding how environmental conditions affect both linings and substrates, facility managers can make informed decisions that extend service life, improve safety, and reduce long-term maintenance costs.

The right lining isn’t just a coating; it’s a vital part of your asset protection and service life strategy.

Contact Us

Our team can assist in evaluating your application and helping you find the right solution tailored to your conditions. Sauereisen offers expert advice on product solutions for corrosive environments and provides application guidance tailored to your needs. We’ll help you find the right solution – Contact us at www.sauereisen.com or call Sauereisen at +1 (412) 963.0303 – Let’s talk before you pour, trowel or spray.