Concrete is the most widely used building material, but in tougher conditions, it can deteriorate due to various factors. Understanding the causes of concrete degradation and the ways to prevent it can help ensure the longevity and safety of concrete structures. Below, we explore the main types of concrete degradation, their causes, and effective prevention methods

Types of Concrete Corrosion and their Causes

1. Chemical Attack

Chemical attack occurs when reactive substances in the environment interact with the components of concrete, resulting in deterioration.

Causes:

- Acids and Bases: Concrete is susceptible to acidic or alkaline substances, which can weaken the material by dissolving calcium compounds and causing surface, or greater, degradation.

- Sulfate Attack: Sulfates in groundwater or soil, or from various chemical exposures, can react with the calcium hydroxide in concrete, leading to the formation of expansive compounds that crack, spall and degrade the concrete.

2. Freeze-Thaw Damage

Freeze-thaw damage occurs when moisture trapped within the concrete freezes, causing it to expand and exert internal pressure, which can lead to cracking and spalling.

Causes:

- Water Infiltration: Concrete exposed to cycles of freezing and thawing in cold climates can suffer damage when water within the pores of the concrete freezes and expands. Water infiltration can also cause rebar corrosion, which can result in expansive pressures resulting in cracking and spalling.

- Air Entrainment Deficiency: Concrete that lacks sufficient air pockets to accommodate the expansion of frozen water is more susceptible to freeze-thaw damage.

3. Compressive or Tensile Stresses

Concrete is strong in compression but weak in tension. Over time, structures can experience excessive loading or environmental stress, leading to cracking or structural failure.

Causes:

- Excessive Loading: Overloading concrete structures with weight beyond their designed capacity can lead to cracking, deformation, or failure.

- Tensile Stresses: Concrete’s inherent weakness in tension makes it prone to cracking under stretching or bending forces, especially if insufficient reinforcement is used.

4. Erosion and Abrasion

Erosion and abrasion damage concrete by physically wearing down the surface, often due to high-impact conditions, heavy traffic, or harsh environments.

Causes:

- High Traffic Loads: Concrete subjected to repetitive impacts, such as forklifts, trucks, or machinery, can experience surface wear that erodes the material over time.

- Exposure to Abrasive Materials: Concrete surfaces exposed to abrasive materials like sand, gravel, or industrial waste can suffer from continuous wear, resulting in surface degradation.

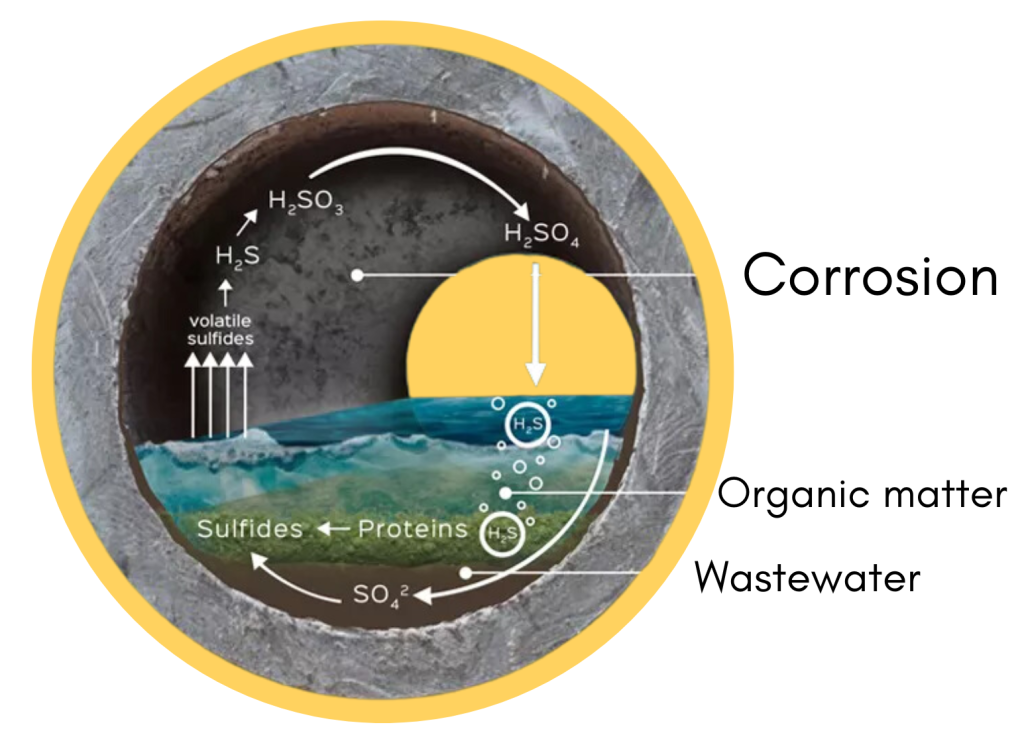

5. Biological Degradation

Biological degradation occurs when microorganisms, such as bacteria or fungi, grow on concrete surfaces and produce acids or other byproducts that accelerate the breakdown of the material.

Causes:

- Microbial Growth: Microorganisms, particularly in the head spaces and vapor zones of structures, can produce organic acids that attack the concrete surface, leading to erosion or weakening of the structure.

- Organic Material Buildup: Accumulation of organic materials, such as plant debris, can provide a medium for microbial growth.

How to Prevent Corrosion

Use of High-Strength Concrete Substitute (Polymer Concretes): Polymer concrete, which incorporate corrosion resistant polymers as binders rather than Portland cement, enhance the concrete’s chemical and biological resistance, and can be used in areas exposed to harsh environments.

- Expansion Joints: Properly placed expansion joints can prevent the buildup of moisture that may promote microbial activity and reduce freeze thaw issues resulting from open cracks.

- Corrosion Resistant Coatings: Apply corrosion resistant coatings that will resist acids and alkaline compounds that can degrade the concrete.

- Cleaning and Maintenance: Regularly clean concrete surfaces to remove organic material and prevent microbial buildup that could lead to degradation.

- Routine Inspections: Conduct regular inspections to identify early signs of degradation, such as corrosive attack, cracks, discoloration, or surface wear.

Sauereisen offers Engineered Solutions corrosive environments everywhere.

Protect your valuable investment with the engineered systems that last. At Sauereisen, we draw upon over 126 years of industry experience to produce high-quality corrosion resistant products. Contact us at www.sauereisen.com or call Sauereisen at +1 (412) 963.0303 today — the first step toward long-term protection. We’ll help you find the right solution.