Stack Liners

Chimneys exposed to high exit gas temperatures may need gunite Refractory or brick-and-mortar systems. Conditions like high heat, abrasion, by-pass flow, and corrosive gases can be addressed using inorganic potassium silicate or calcium aluminate materials. A high-temperature organic membrane behind the refractory has proven effective in extending liner life. Sauereisen provides materials to maintain and repair aging liners.

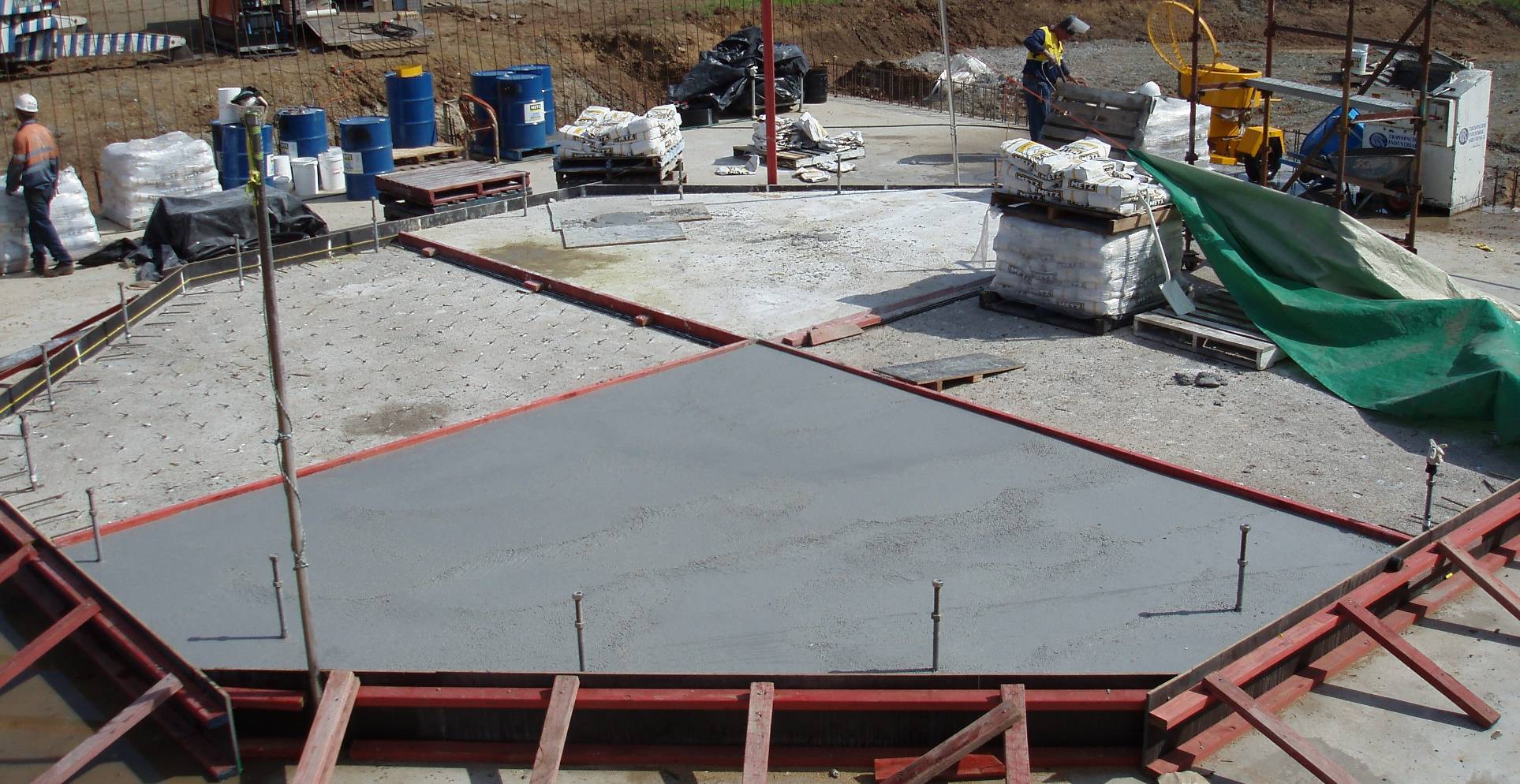

Floors

When considering replacement of brick & mortar stack floors or repairing existing structures, the use of inorganic potassium silicate or calcium aluminate polymer concretes may be preferred versus a gunite application or brick restoration. These polymer concretes are installed by casting. A continuous mixer can be used to increase application efficiencies. These products can also be used in the construction of sumps, dikes, trenches, and columns exposed to acidic conditions. Sauereisen Polymer Concretes reduce costly down-time with return to service in 48 hours or less.

Ducts

Bypass ducts carrying hot, acidic gases are well-suited for economical dual-lining systems like 89/54, 89/54LW, or 89/35, selected based on temperature, chemistry, and operating conditions.

Scrubber Ducts contain lower temperature gases which allow for the use of vinyl ester & epoxy fiber-reinforced novolak lining systems. The incorporation of fiber into the resin system increases the tensile & flexural strength of the resin system and resistance to vapor & liquid permeation. The fiber-reinforced linings offer a faster & more economical alternative to mat-reinforced systems.

Cooling Towers

Biocide chemicals, freeze/thaw cycling, and potential bacterial corrosion are common problems that cause concrete damage in cooling towers. Repairing and restoring the structural integrity is quickly accomplished with Sauereisen F-120 ShotCrete material.

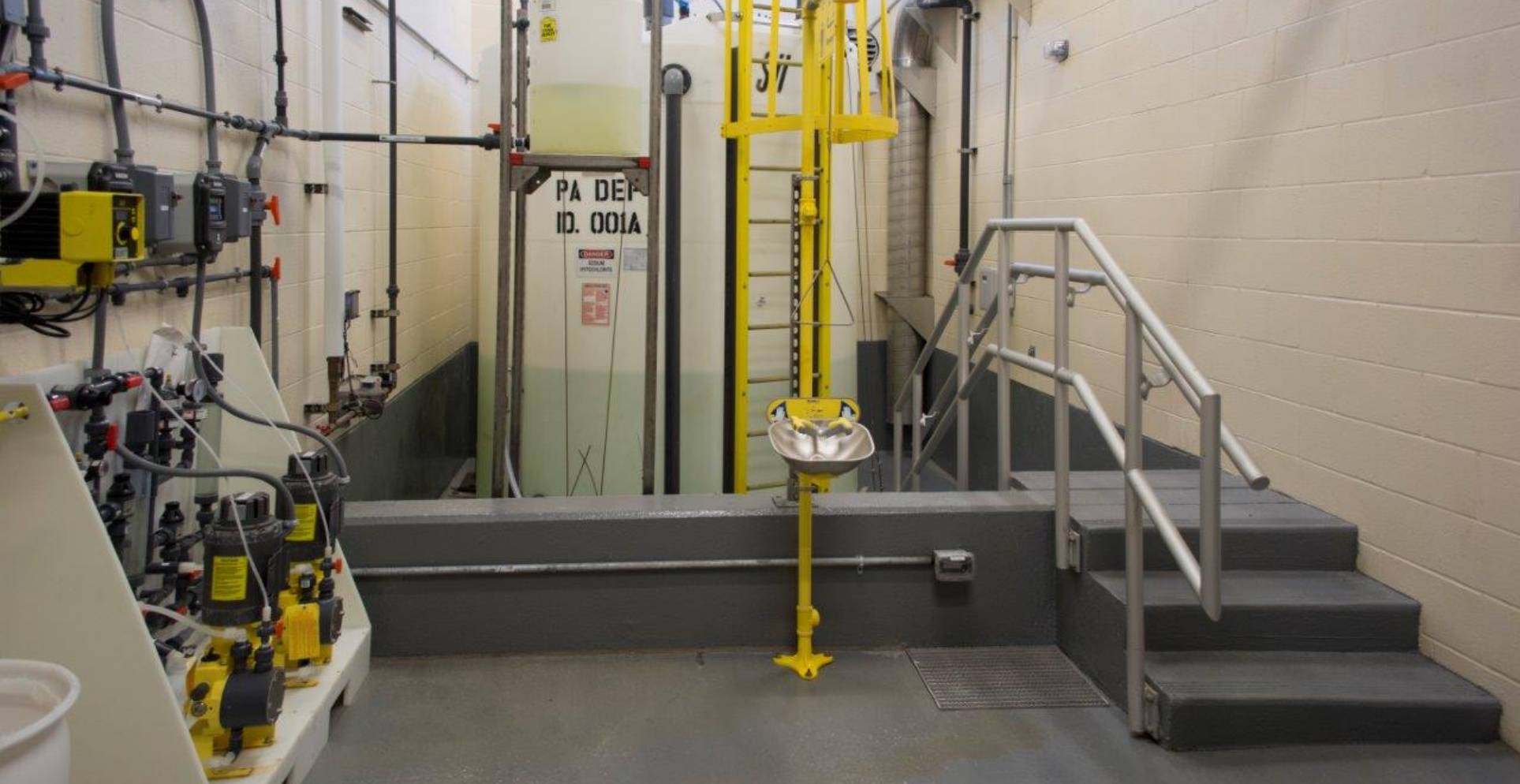

Water Treatment

Wastewater from the FGD process is collected and purified before emitted in the aquafer system. The collection tanks, trenches, clarifiers that separate solids and other treatment areas require protection. Most applications are well-suited for fiber-reinforced epoxy lining systems. Neutralization basins may require a furan mortar brick system or an organic, polymer concrete for rehabilitation.

The SewerGard® Industrial line is specially formulated materials for protection of concrete or steel structures common to industrial wastewater collection systems.